Recent digital transformation has outpaced traditional paper and pencil drafting practices. Modern CAD revolution reached from mere 2D CAD design to 3D CAD design, and 3D modeling has added much fuel to the engineering service industry. The debate on 3D CAD design vs. 3D CAD modeling seems insignificant because 3D CAD design and drafting come first in the process to achieve sharp precisions in 3D CAD modeling.

Today, I will illustrate the top seven advantages of 3D CAD modeling in the engineering service industry. The engineering service industry is gaining momentum thanks to increasing trends toward outsourcing engineering prototyping and product design work.

Top 7 Benefits of 3D CAD Modeling for Engineering Services

1. Enhanced Visualization and Communication between the Engineering Team and client.

- 3D CAD modeling is a digital design process visually representing an engineering model.

- software enables the engineering or product design team to build a detailed and precise 3D model of their entire plant, assembly, construction property, or product.

- Thus, the engineering team can comprehend the design’s geometry, functionality, and aesthetics.

- 3D modeling encourages communication among all stakeholders, internal team members, and client-side teams.

- It fills gaps between technical and non-technical stakeholders of the project by producing technically sound yet aesthetically pleasing engineering models on the digital landscape.

- 3D models simplify intricate design concepts and facilitate further iterations in the design with design and client teams.

- It efficiently conveys the design messages and reduces the likelihood of misunderstandings in 2D design projects.

2. 3D CAD Modeling Brings Precisions in Design:

- Design accuracy and precision are crucial factors in industries where tolerance is paramount. For instance, aerospace, automotive, and medical device design and manufacturing industries.

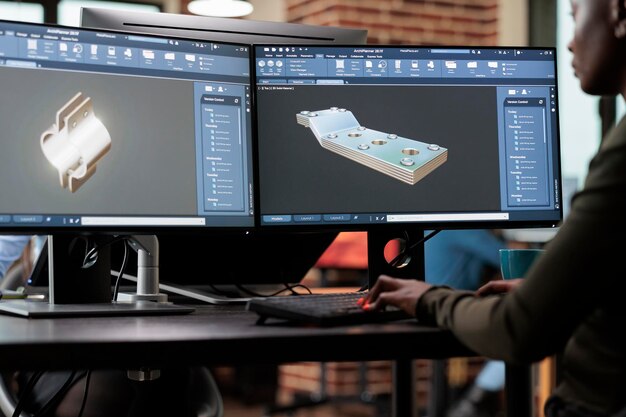

- 3D CAD design and drafting software lets designers and engineers input precise dimensions, angles, curves, and shapes in design tools.

- 3D modeling tools convert 3D CAD design into 3D objects meeting engineering and visual expectations, such as materials, surface finishes, and textures with real-life dimensions and shapes.

- 3D CAD Modeling software has the ability to conduct interference checks and provide simulation to recognize and rectify potential design flow before the manufacturing process.

3. Rapid Prototyping & Product Iteration:

- 3D modeling in digital space allows fast changes in various aspects of the model without much impact on cost.

- Therefore, the design team can create plenty of design options or variance, providing rapid virtual prototyping opportunities.

- Moreover, the design and development team can create product iteration for quirk refinement of the design concept from scratch or for minor modifications. Thus, customers can obtain a satisfied design at the end by giving feedback.

4. Cost-saving in Product Development:

- Physical models were essential to prototyping and design iteration in traditional engineering product development. It consumes a lot of time and considerable costs in materials and labor. Digital 3D models save everything and give flexibility as a bonus.

- 3D CAD models provide accurate simulation and analysis tools to optimize design for efficiency, performance, and durability. Thus, it cuts the risks of costly design flow considerably.

5. Global Teamwork & Collaboration:

- Outsourcing is a trend, and 3D modeling service providers get projects from offshore clientele from different time zones.

- 3D CAD modeling service teams are often spread across different global locations.

- Modern 3D CAD design and 3D CAD modeling systems have been created, keeping global collaboration among team members and client-side teams in mind.

- Therefore, the software supports global teamwork and collaboration by providing access, review, and modifying tools to make real-time design changes and enable the team to exchange their thoughts/ideas and expertise by working irrespective of geographical boundaries.

6. Streamlined Design & Manufacturing Processes:

- 3D CAD design and modeling software have been designed to streamline transit from design to manufacturing.

- Users can use models directly to provide manufacturing instructions, CNG toolpaths, and 3D printing prototypes.

- Thus, the final product can adhere to the initial design intent.

- 3D modeling software also supports delivering detail assembly instructions and explod views of products to make the assembly process error-free and efficient.

7. Cornerstone in PLM (Product Lifecycle Management):

- Digital 3D models can act as the cornerstone of the product lifecycle management systems.

- 3D models provide a digital representation of the products throughout the product life cycle. So, you can get complete clues/pictures of the initial design to manufacturing, maintenance, and product retirement stages.

- It gives all stakeholders efficient version control, documentation, and change management.

- Thus, it gives access to all stakeholders to the latest and most accurate information.

Wrapping Up:

3D CAD design and 3D CAD modeling have emerged as pivotal technologies in engineering fields. It delivers multitudes of advantages ranging from enhanced visualization and communication to streamlined manufacturing processes. It profoundly impacts time, cost, and design quality for engineering services. It aids in improving accuracy and efficiency and gives a competitive edge in the market.

Shalin Designs enjoys a reputation in engineering services fields thanks to its talented pool of 3D CAD designers and modelers ready to provide cost-effective services at highly competitive rates. Would you like to discuss your next project with our experts?