The electronics industry is constantly evolving to meet the demands of consumers’ needs of advanced and innovative products. To keep up with this ever-changing landscape, electronics manufacturers turn to CAD design to gain a competitive edge. CAD has become an indispensable tool in the electronics industry, offering a plethora of benefits that streamline the design process, enhance product quality, and foster innovation.

Here, you will explore how CAD design is reshaping the electronics industry and its remarkable advantages.

What is CAD Design in the Electronics Industry?

CAD is specialized software applications to design, visualize, and optimize electronic components and systems. It enables engineers and designers to create schematic diagrams, PCB layouts, and 3D models of electronic devices. This helps engineers to visualize their designs, identify potential problems, and ensure that the designs meet the required specifications.

Advantages of CAD Design in Electronics Industry:

1. Faster Product Development:

CAD design expedites the electronics product development process significantly. Gone are the days of tedious manual drafting; designers now leverage CAD to swiftly create and iterate product designs. For example, a smartphone manufacturer can use CAD to visualize and fine-tune the layout of internal components, resulting in a faster time-to-market for cutting-edge devices.

2. Enhanced Design Accuracy and Precision:

With CAD designing, electronics designers can achieve unparalleled precision and accuracy in their designs. The software’s sophisticated measurement tools ensure that each component fits perfectly, minimizing the risk of errors during manufacturing. A prime example of this benefit can be seen in the design of intricate microchips where even the tiniest discrepancies can cause functionality issues.

3. Realistic Visualization and Simulation:

CAD’s 3D modeling capabilities enable designers to create lifelike representations of electronic products. This facilitates a better understanding of the final product before the costly physical prototyping stage. Additionally, CAD’s simulation tools allow designers to analyze how components interact and predict potential issues. For instance, a PCB designer can simulate the flow of electricity through the board to optimize its layout and avoid signal interference.

4. Seamless Collaboration and Communication:

CAD design fosters efficient collaboration between various teams involved in the electronics industry. Designers, engineers, and manufacturing experts can seamlessly share design files, provide feedback, and make revisions in real time. Such collaboration empowers teams to work cohesively, leading to improved teamwork and accelerated product development cycles.

5. Cost Savings and Resource Optimization:

By detecting design flaws early on, CAD design reduces the need for costly physical prototypes and rework. This not only saves money but also optimizes resource utilization, making the entire product development process more cost-effective. For instance, an electronics startup can allocate saved resources to research and development, leading to groundbreaking innovations.

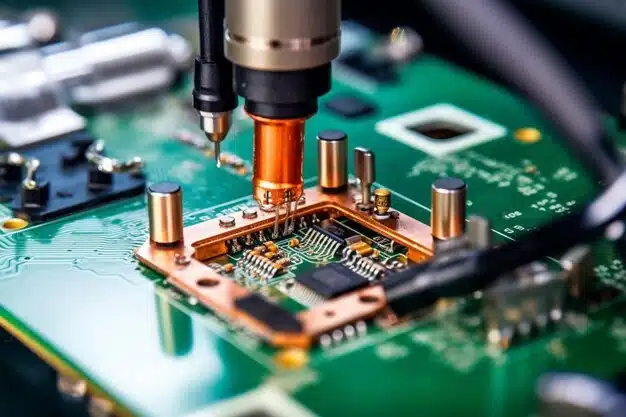

6. Integration with Manufacturing Processes:

Modern CAD software integrates smoothly with computer-aided manufacturing (CAM) and computer-aided engineering (CAE) tools. This seamless integration enables a smooth transition from design to production, ensuring that the design data can be directly utilized in PCB fabrication and assembly. For example, a PCB designer can export the design files directly to the manufacturer’s production line, streamlining the manufacturing process.

7. Design Optimization for Peak Performance:

CAD empowers designers to explore various design options and configurations rapidly. By analyzing different materials and parameters, designers can optimize electronic products for peak performance. As an example, a laptop manufacturer can use CAD to experiment with various heat sink designs, ensuring efficient heat dissipation and improved device performance.

8. Management of Complex Designs:

With the increasing trend of miniaturization and integration in electronics, managing complex designs has become critical. CAD design services are tailored to handle intricate designs, ensuring that all components are properly placed and routed. For instance, a wearable tech company can use CAD to meticulously design a compact fitness tracker with integrated sensors and a long-lasting battery.

Moreover, CAD not only boosts productivity but also ensures that electronic products are of the highest quality, ultimately benefiting both manufacturers and consumers alike. As the electronics industry continues to evolve, Computer-Aided Design has revolutionized the electronics industry, making it possible for manufacturers to stay at the forefront of innovation and meet the growing demands of consumers.

If you are also looking for modification in your electronic industry, then look no further just contact us at info@shalindesigns.com today or drop a message here. We would be happy to discuss your project and how we can help you create stunning and functional electronic products and layouts that will meet your needs.