The maritime industry has experienced a sea change with the advent of 3D modeling technology. This transformative tool has revolutionized how ships, offshore structures, and maritime operations are designed, managed, and executed.

Let’s dive into the profound impacts of 3D Modeling in the Maritime industry.

Impacts of 3D Modeling in Maritime Industry

1. Enhanced Ship Design and Construction

3D modeling has upended traditional ship design and construction methods. It allows naval architects and engineers to create intricate and accurate vessel designs with a level of detail unimaginable before. From hull geometry to cabin layouts, every element can be meticulously crafted in the virtual realm, leading to vessels that are not only efficient but also optimized for safety and performance.

2. Efficiency in Vessel Operations

3D modeling’s influence extends beyond the drawing board. Shipowners and operators leverage 3D models to simulate maritime operations, optimizing routes, cargo distribution, and fuel consumption. This proactive approach not only saves costs but also contributes to environmental sustainability by minimizing unnecessary fuel consumption.

3. Revolutionizing Maintenance and Repairs

Maintaining maritime assets is a formidable challenge. 3D modeling has provided a lifeline by enabling precise digital representations of vessels and structures. Maintenance crews can access detailed models to strategize repairs, anticipate wear and tear, and reduce downtime. This leap from reactive to preventive maintenance enhances efficiency and ensures safer journeys.

4. Advancing Offshore Platform Designs

The offshore industry has embraced 3D modeling to reimagine platform designs. Complex structures like oil rigs and wind farms benefit from 3D models that simulate various scenarios, including harsh weather conditions. Engineers can optimize these structures for durability and stability, minimizing risks and enhancing operational longevity.

5. Navigating through Training Simulations

Maritime training has also seen a transformation. 3D models facilitate immersive simulations for crew members, enabling them to practice emergency procedures, navigation challenges, and equipment operations in a virtual environment. This hands-on training hones skills, ensuring preparedness for real-world scenarios.

6. Harboring Safety and Sustainability

Safety is paramount in the maritime industry, and 3D modeling contributes significantly. By digitally testing vessels and structures before they hit the water, potential hazards can be identified and rectified. Moreover, the optimization of maritime operations reduces environmental impact, aligning with the industry’s push for sustainability.

7. Shaping the Future of Maritime Exploration

Underwater exploration benefits immensely from 3D modeling. Autonomous underwater vehicles (AUVs) use 3D mapping to explore and chart the ocean’s depths. These models aid researchers in understanding marine ecosystems, underwater geology, and even potential archaeological sites.

How is 3D Modeling revolutionizing ship design and construction processes?

3D modeling has ignited a profound transformation in ship design and construction processes, redefining how vessels are conceptualized, planned, and brought to life. This revolution is marked by several pivotal advancements:

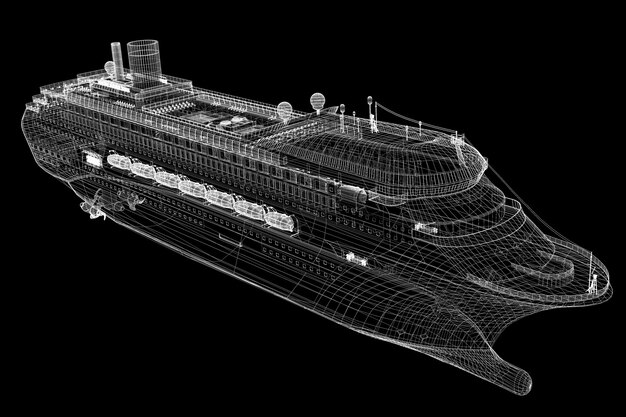

Precision and Detail:

3D modeling allows for the creation of intricate ship designs with unparalleled precision and detail. Naval architects and engineers can develop every aspect of a vessel in a digital environment, from its hull structure to interior layouts. This level of accuracy ensures that every component fits seamlessly, minimizing errors and rework during the construction phase.

Virtual Prototyping:

Traditional ship design relied heavily on physical prototypes, which were time-consuming and expensive to produce. With 3D modeling, virtual prototypes come to the forefront. Engineers can visualize the entire vessel, identify design flaws, and test different configurations without the need for physical models. This streamlined process accelerates design iterations and reduces costs.

Realistic Simulations:

Ship design involves navigating through various scenarios, from calm seas to challenging weather conditions. 3D modeling enables designers to simulate how vessels will behave under different circumstances. This allows for accurate predictions of stability, performance, and safety, ensuring that ships are optimized for real-world challenges.

Collaborative Design:

Collaborative efforts among multiple teams – architects, engineers, interior designers, and more – are essential in ship design. 3D modeling platforms provide a central hub where these teams can work together seamlessly. Real-time collaboration and instant feedback facilitate better coordination and communication throughout the design and construction phases.

Reduced Build Time and Costs:

The ability to create accurate 3D representations of ships significantly reduces the need for physical mock-ups and prototypes. This translates to shorter design cycles and reduced build times. Moreover, identifying design flaws and potential clashes in the digital realm minimizes rework and costs.

Customization and Innovation:

Shipowners today demand vessels tailored to their specific needs. 3D modeling caters to this customization requirement by allowing designers to create bespoke designs. Innovative features, layouts, and functionalities can be easily integrated, pushing the boundaries of ship design possibilities.

Clear Communication:

Traditional 2D drawings often require interpretation, leading to misunderstandings and miscommunication. 3D models offer a clearer representation of the ship’s design. Stakeholders, including shipowners, operators, and regulatory bodies, can grasp the design intent more easily, leading to better-informed decisions.

Visualizing Complex Systems:

Modern vessels are equipped with intricate systems, from engine rooms to navigation controls. 3D modeling enables a visual representation of these complex systems, making it easier for engineers to optimize layouts, ensure accessibility for maintenance, and enhance overall functionality.

In essence, 3D modeling has reimagined ship design and construction by offering a holistic, dynamic, and immersive approach. It empowers designers to create vessels that are not only aesthetically appealing but also technically superior, safe, and efficient. The revolution continues as this technology evolves, shaping the future of shipbuilding in unprecedented ways.

Moreover, if you are looking for a 3D Model designer for any industry or Product development? Then look no further, just drop a message here, or drop an email to info@shalindesigns.com. We would be happy to create a 3D Model of your design project. Get your all project design solutions with Shalin Designs.