CAD software, CAD design, and their various techniques are integral to mechanical engineering and manufacturing. These tools support designers and engineers in crafting products that meet market demands and comply with thermodynamic concepts. Leveraging these tools effectively often requires professional support, which is where mechanical design & drafting services come into play.

Here you can explore the varied tips and tricks mechanical engineers follow while designing products before manufacturing.

Key Mechanical Engineering Foundations for CAD Design

Mechanical engineering is based on a few core concepts. They are:

– Kinematics and Dynamics

Kinematics is a concept that focuses on the motion of objects. It analyzes the object’s performance by considering factors like velocity and acceleration. On the other hand, dynamics defines and assesses the forces that cause motion in the object.

Both kinematics and dynamics enable engineers to understand how mechanical forces behave under diverse conditions. This further helps designers meet the performance requirements.

– Strength of Materials

It focuses on the properties of materials. To be precise, the strength of materials examines the ability to withstand loads. Therefore, stress, strain, and material behavior are used to create durable and sustainable products. They also use finite element analysis (FEA) to create durable and sustainable products while making mechanical CAD designs. This helps the engineers to simulate and analyze how the product will perform under certain conditions.

– Thermodynamics and Fluid Mechanics

Thermodynamics is the study of energy transfer and conversion processes. On the other hand, fluid mechanics involves the analysis of fluid behavior in motion or at rest. It’s worth noting that both of these concepts are vital for mechanical engineers designing their systems.

Both thermodynamics and fluid mechanics are essential for understanding energy transformation. Thus it’s vital for designing engines and HVAC systems. Understanding these concepts helps engineers optimize products and increase efficiency in mechanical designs.

Struggling with Complex Mechanical Drafts?

Let our CAD experts simplify your design challenges with precise 2D drafting and advanced 3D modeling. Get a free consultation today.

Applying CAD in Mechanical Engineering

Here are the significant applications of CAD in mechanical engineering:

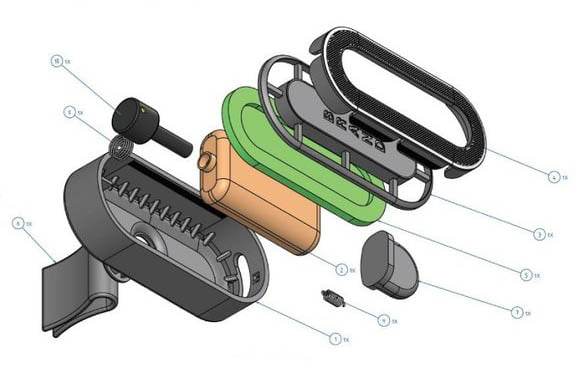

1. 3D Modeling of Mechanical Components

3D modeling lies at the center of mechanical engineering design and drafting services. It allows engineers and designers to represent the product and assemblies accurately.

Prototyping and customization are two integral applications of 3D modeling & CAD designs. While the rapid prototyping process enables designers to create 3D models, customization meets client requests. It allows engineers to modify the prototype according to the client’s preferences. This enhances flexibility in designs.

The benefits include:

- Enhanced visualization of how components fit together. It allows mechanical engineers to identify potential flaws and rectify them one time.

- Teams can share these designs digitally and collaborate in real-time. Using this method, designers can come up with more innovative solutions.

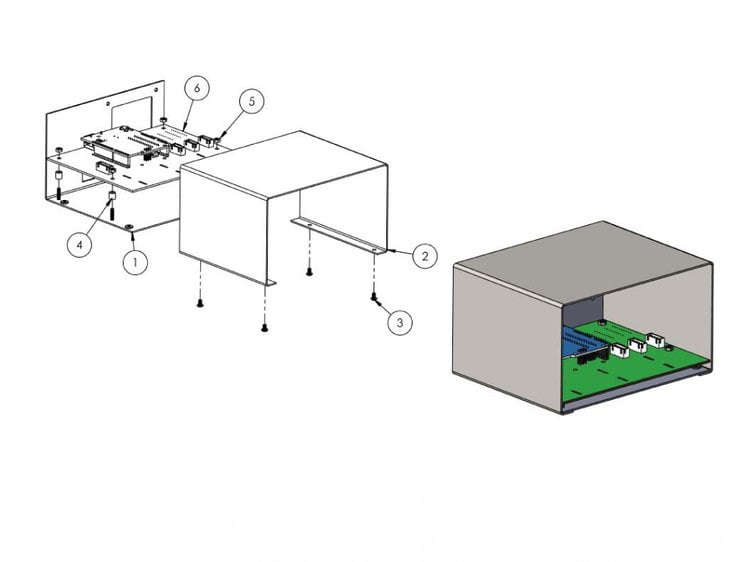

2. Finite Element Analysis (FEA)

It is a powerful simulation technique that can predict how CAD designs react under specific loads. Structural components and thermal analysis are two significant applications.

The structural components are often used in the aerospace and automotive industries. It analyses components like wings, frames, and more. Secondly, manufacturing design & drafting services use FEA for thermal simulation to understand if products can withstand temperature.

FEA helps in the following:

- Allows engineers to observe stress distribution across the model.

- Simulates different components and enables engineers to optimize designs to save weight and manufacturing costs.

3. Computational Fluid Dynamics (CFD)

CFD numerically measures the fluid flow and energy transfer of systems. In aerospace engineering, designers use CFD to design aircraft wings and fuselage shapes. It’s also used for HVAC systems where engineers use CFD to ensure proper airflow within buildings. CFD also ensures the heating, ventilation, and air conditioning systems run efficiently.

It’s beneficial to engineers because:

- CFD allows you to identify design flaws through simulation. That way, designers can quickly make the modifications before manufacturing.

- This kind of simulation tool allows engineers to optimize product performance.

4. Mechanism Design and Simulation

This is a tool that assists engineering designers in creating motion-converting systems. It is essential in robotics, creating joints and linkages for complex movements. In the automotive industry, CAD contributes to designing gear systems, linkages, and many other assemblies.

Some advantages include:

- Simulate the motion of mechanisms and analyze the functionalities under various conditions.

- Reduces prototyping costs and validates designs by saving manufacturing time.

Advanced CAD Techniques for Mechanical Engineers

Some impactful methods are:

– Sheet Metal Design and Drafting

Sheet metal design refers to the process of creating components from thin metal sheets. Advanced CAD tools help engineers create 3D representations of products before manufacturing.

Key features:

- Automatically generates flat patterns by reducing manual calculations and human errors.

- Bend allowances ensure all components fit together before manufacturing

– Mould Design and Analysis

In industries like automotive and consumer goods, mould design is essential. Such advanced CAD techniques empower engineers to create plastic components using injection moulding.

Key features:

- Manufacturing design & drafting services ensure uniform temperature distribution through cooling channels within the moulds.

- CFD integrated within the CAD software enables engineers to identify how fluids flow within the moulds. It helps manufacturing designers avoid potential defects.

– Tolerance Analysis and Stack-Up

It ensures that all components fit together as per the design. Mechanical CAD designs created by advanced tools provide a detailed analysis of tolerance on assemblies.

Key features:

- Automatically calculates the effect of tolerances across multiple assemblies.

- Offers quality assurance of products by carrying out practical tolerance analysis

Conclusion

Once you know the core concept of mechanical engineering and its application in CAD, there is absolutely nothing that can stop you from achieving CAD mastery for an enhanced product design. The core concepts of mechanical engineering will sharpen your mechanical engineering design and drafting services. Along with it, using moulding & tolerance analysis will be a cakewalk.

Ready to optimize your mechanical product designs? Get in touch with Shalin Designs, India’s frontline design and drafting service provider. Access Brand’s manufacturing design & drafting services have catered to hundreds of clients across the globe by designing innovative products.