In today’s fast-paced world, businesses are constantly seeking ways to improve efficiency while minimizing costs. One of the most powerful tools at their disposal is 3D CAD design. This technology has transformed the way companies approach design projects, offering significant time and cost savings. Whether it’s in architecture, product development, or furniture design, 3D CAD models provide unmatched accuracy, flexibility, and the ability to foresee potential problems before they arise.

Shalin Designs has been a leader in offering comprehensive 3D CAD design services for industries such as furniture, millwork, and manufacturing. Let’s explore how leveraging 3D CAD can optimize your design process, ultimately leading to faster project completion and lower expenses.

Key Benefits of 3D CAD Design

1. Improved Accuracy and Reduced Errors

Traditional 2D designs often leave room for misinterpretation, which can lead to costly errors during manufacturing or construction. 3D CAD design allows for precise visualization of all aspects of a project, reducing the risk of mistakes. Components are modeled in a digital space, ensuring every detail is accounted for before any physical work begins. This eliminates the need for rework, saving valuable time and money.

Shalin Designs, for example, utilizes 3D CAD modeling to ensure that custom furniture and millwork projects are executed flawlessly. Clients can view the design in detail and make changes before it reaches the production phase, minimizing errors that could otherwise result in material waste and labor costs.

2. Streamlined Collaboration

Design projects often involve multiple stakeholders, including designers, engineers, and clients. Communicating ideas effectively in 2D can be challenging, leading to miscommunication and delays. With 3D CAD modeling, everyone involved can view and interact with the design in real-time, ensuring a clear understanding of the project from start to finish.

Shalin Designs uses 3D CAD services to share detailed models with clients, helping them visualize the final product. This clarity reduces back-and-forth communication, speeds up decision-making, and ensures the project stays on schedule.

3. Faster Design Revisions

Revising designs is an inevitable part of any project. In a 2D design, changes can be cumbersome and time-consuming, requiring designers to redraw or manually update drawings. 3D CAD design simplifies this process by allowing instant modifications to the model. Whether you’re adjusting dimensions, and materials, or adding new features, the changes are reflected instantly.

At Shalin Designs, clients often request modifications to custom furniture pieces or millwork designs. With 3D CAD modeling, these revisions can be implemented quickly, ensuring the project progresses without unnecessary delays.

4. Cost-Effective Prototyping

Prototyping is often one of the most expensive parts of product development. Building physical prototypes takes time, materials, and labor. With 3D CAD design, digital prototypes can be created and tested virtually, allowing companies to identify issues before committing to a physical prototype.

For example, Shalin Designs creates virtual 3D furniture models that enable clients to see how a piece will look in a room, test different materials, and make adjustments. This eliminates the need for multiple physical prototypes, saving both time and money.

5. Optimized Material Use

One of the hidden costs in any design or manufacturing project is material waste. Traditional methods may result in cutting or ordering too much material, leading to unnecessary expenses. 3D CAD models provide precise measurements and show how teams can use materials efficiently, allowing for optimized allocation and reduced waste.

Shalin Designs leverages 3D CAD modeling to ensure custom millwork and furniture projects are designed with minimal material waste. The precise measurements provided by the software allow manufacturers to cut materials with exactness, further contributing to cost savings.

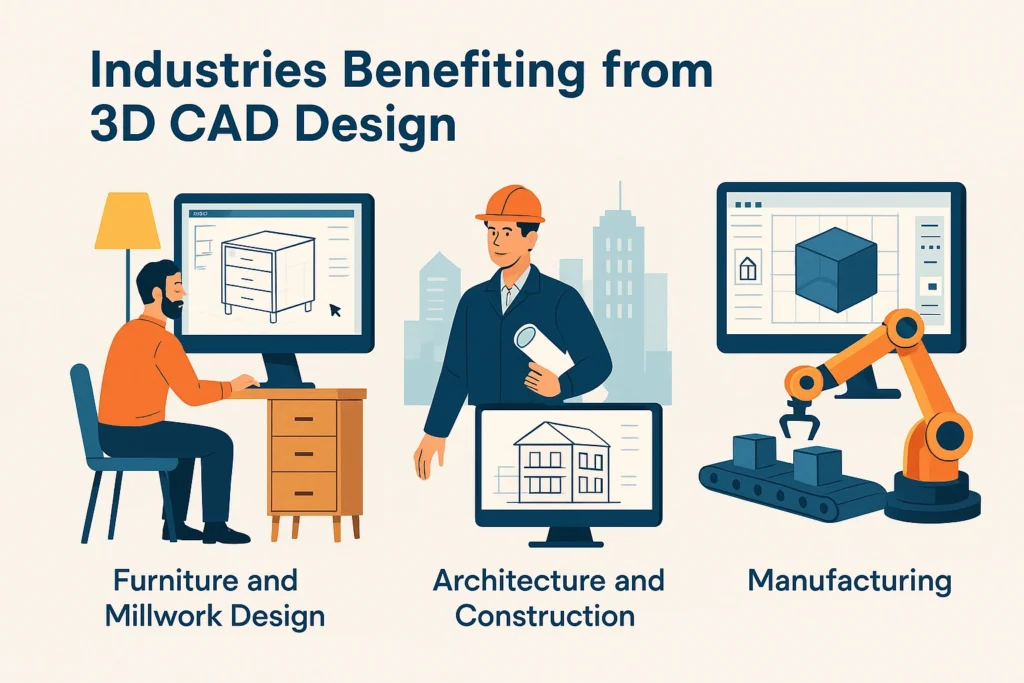

Industries Benefiting from 3D CAD Design

Furniture and Millwork Design

In furniture and millwork design, 3D CAD modeling is crucial. It allows for the creation of intricate and detailed designs that can be modified easily and accurately. Shalin Designs specializes in transforming 3D models into detailed 2D furniture drawings, which are used for manufacturing. This process saves time by ensuring that designers align every element perfectly with manufacturing capabilities.

Architecture and Construction

In architecture, 3D CAD design helps architects and contractors visualize and refine structures before construction begins. It allows for quick adjustments and ensures that everyone involved in the project can see exactly what the final building will look like. By spotting potential issues early, architects can avoid costly revisions during construction.

Manufacturing

Manufacturers benefit immensely from 3D CAD drawings because it improves product accuracy, reduces lead time, and optimizes the use of raw materials. Shalin Designs has worked with numerous manufacturing clients, helping them streamline their processes with accurate 3D CAD models that reduce production errors.

How 3D CAD Drawings Saves Time?

1. Faster Design Cycles

The ability to visualize and test designs digitally means that design cycles are shorter. What once took weeks or months can now be done in days. This is especially true when working with complex designs that would be difficult to represent in 2D. 3D CAD design allows you to build, test, and refine a model in a fraction of the time.

2. Quick Client Approvals

Client approvals often slow down the design process, especially when working with traditional drawings. With 3D CAD models, clients can instantly see what the final product will look like and make quicker decisions, which accelerates the approval process.

3. Integration with Automated Manufacturing

Automated manufacturing systems can directly integrate 3D CAD designs, enabling seamless transitions from design to production. This eliminates the need for manual translation of drawings, significantly speeding up the production process.

Get High-Quality 3D CAD Design Services in the USA, UK & UAE!

Our global CAD experts deliver cost-effective, accurate 3D designs tailored to your industry needs. Perfect for architecture, manufacturing, and furniture design.

How 3D CAD Design Services Saves Money?

1. Reduced Labor Costs

By eliminating the need for rework and physical prototyping, 3D CAD drawings significantly reduces labor costs. Shalin Designs has helped clients save on production by ensuring that every design detail is perfect before any work begins.

2. Minimized Waste

As mentioned earlier, 3D CAD modeling optimizes material use, reducing waste and saving money on raw materials. This is particularly beneficial for industries such as manufacturing and furniture design, where material costs can be a major expense.

3. Lowered Risk of Delays

Delays are costly. They increase labor, rental, and material costs, especially when working with large-scale projects. 3D CAD design allows you to foresee potential issues early on, reducing the risk of delays and keeping projects within budget.

Conclusion

Incorporating 3D CAD design into your workflow is a smart decision that offers both short-term and long-term benefits. 3D CAD models improve accuracy, streamline collaboration, and reduce waste, helping teams complete projects faster and with fewer errors. At Shalin Designs, we specialize in providing 3D CAD modeling services that help clients save time and money, no matter the industry.

Ready to start optimizing your next project? Contact Shalin Designs today to discover how 3D CAD design can transform your design process and help you achieve better results faster.