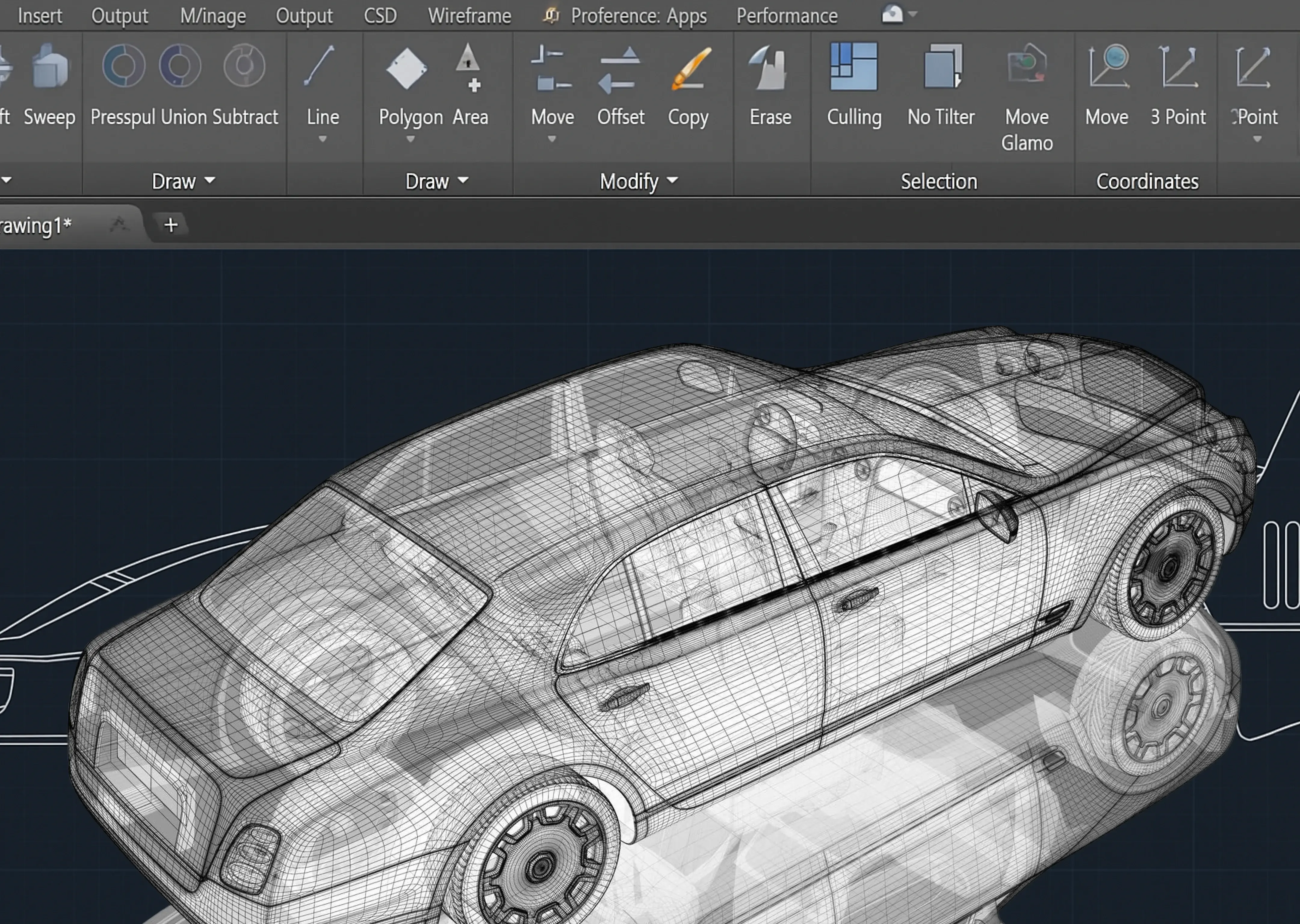

In the dynamic world of car manufacturing, precision and innovation are the driving forces that shape the industry. This is where CAD Drawing comes into play, revolutionizing the way cars are conceptualized, designed, and brought to life.

Computer-aided design (CAD) is a technology that has revolutionized the car manufacturing industry. CAD software allows engineers to create detailed 3D models of cars, which can be used to simulate their performance and test different design ideas. This has led to significant improvements in car safety, fuel efficiency, and overall design. Let’s explore more about the role of CAD drawing in car manufacturing.

What are the benefits of using CAD drawing in car manufacturing?

Using CAD drawing in car manufacturing offers a multitude of benefits that significantly impact the efficiency, quality, and innovation within the industry. Here are some key advantages:

1. Design Precision:

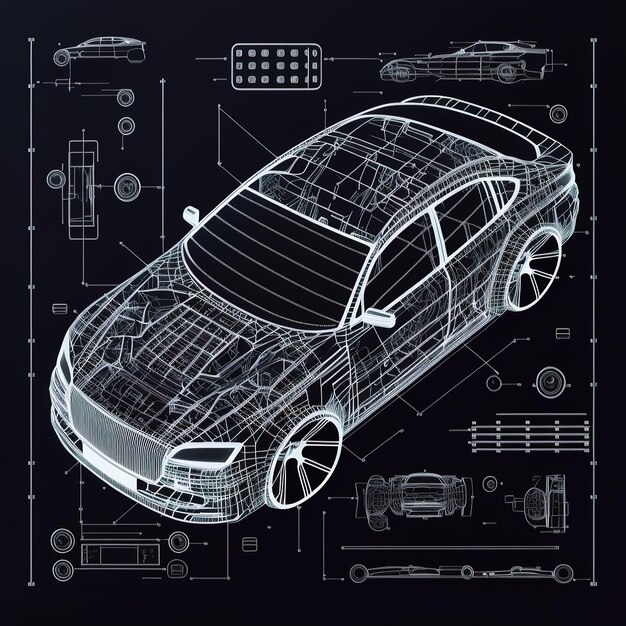

CAD allows designers to create intricate, precise 2D and 3D models of every component of a vehicle. This precision ensures that parts fit seamlessly, reducing the risk of errors and ensuring optimal functionality.

2. Efficient Prototyping:

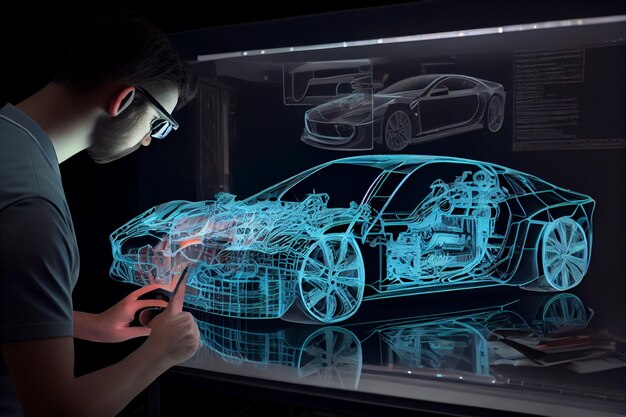

CAD drawing enables virtual prototyping, where designers can visualize and test their ideas digitally. This reduces the need for physical prototypes, saving time and resources.

3. Streamlined Collaboration:

Teams across departments can collaborate seamlessly on CAD platforms. Designers, engineers, and manufacturers can work together in real-time, sharing their insights and making necessary adjustments collaboratively.

4. Time and Cost Savings:

With CAD, designers can quickly iterate and modify designs without the need to start from scratch. This efficiency accelerates the design process and reduces the cost associated with physical changes.

Still Relying on Outdated Drafting Methods?

Switch to CAD drawings that accelerate automotive design and manufacturing.

5. Design Optimization:

CAD tools offer simulations and analyses that allow designers to test different scenarios, ensuring optimal performance, safety, and efficiency of vehicle components.

6. Customization and Personalization:

It allows car manufacturers to offer customization options to customers. Individual preferences can be incorporated into the design without disrupting the overall manufacturing process.

7. Reduced Material Waste:

CAD drawing enables precise measurement and planning, reducing material waste during the manufacturing process. This is particularly important in an era where sustainability is a key consideration.

8. Efficient Manufacturing:

CAD drawings provide manufacturers with clear instructions for assembly and production, leading to smoother manufacturing processes and reducing the likelihood of errors.

9. Innovative Features:

It enables designers to experiment with new materials, technologies, and features that can set a vehicle apart in the market. This promotes innovation and competitiveness.

10 Realistic Visualization:

CAD allows stakeholders to see a realistic representation of the final product before any physical work begins. This visualization aids in decision-making and marketing efforts.

11. Documentation and Record Keeping:

CAD drawings serve as detailed documentation of each vehicle’s design. This record-keeping ensures that future modifications or repairs can be executed accurately.

12. Global Collaboration:

Manufacturers and suppliers from different parts of the world can collaborate seamlessly on a single CAD drawing platform, regardless of their geographical locations.

What role does CAD drawing play in improving the safety of car designs?

CAD (Computer-Aided Design) plays a crucial role in enhancing the safety of car designs in several impactful ways:

* Virtual Prototyping:

CAD allows designers to create digital prototypes of vehicles before any physical manufacturing occurs. This enables thorough testing and simulation of various scenarios, identifying potential safety issues early in the design process.

* Crash Simulation:

CAD drawing offers sophisticated simulation tools to replicate real-world crash scenarios. This helps engineers understand how different components and materials react during a collision, enabling them to design vehicles that absorb impact effectively and protect occupants.

* Structural Integrity:

CAD enables engineers to analyze the structural integrity of vehicle components, ensuring they can withstand different stresses and forces. This includes assessing frame strength, crumple zones, and reinforcement points.

* Ergonomics and Visibility:

CAD facilitates the optimization of driver and passenger ergonomics, ensuring comfortable seating positions and clear visibility of the road. This contributes to minimizing driver fatigue and enhancing overall safety.

* Pedestrian Safety:

It allows for the design of car exteriors with features that mitigate harm to pedestrians in case of a collision. This includes creating energy-absorbing structures and minimizing sharp edges on the front of the vehicle.

* Sensor Integration:

Modern vehicles incorporate a range of safety sensors such as collision avoidance and lane departure warning systems. CAD aids in the placement and integration of these sensors seamlessly into the vehicle’s design.

* Seatbelt and Airbag Placement:

CAD assists in positioning seatbelts and airbags optimally to provide maximum protection to passengers during impact. Engineers can simulate how these safety features deploy in various crash scenarios.

* Material Selection:

CAD allows for in-depth analysis of different materials’ properties and how they respond to stress and impact. This aids in choosing the most suitable materials for different parts of the vehicle, enhancing overall safety.

* Stability and Handling:

CAD tools help engineers optimize a vehicle’s center of gravity, weight distribution, and suspension systems. This contributes to stable handling and reduces the risk of accidents, particularly during maneuvers or adverse conditions.

* Testing Variations:

With CAD, engineers can easily test variations of designs to find the optimal configuration that balances aesthetics, functionality, and safety. This iterative process leads to safer design outcomes.

* Regulatory Compliance:

CAD assists in designing vehicles that comply with safety regulations and standards set by relevant authorities, ensuring that vehicles meet required safety thresholds.

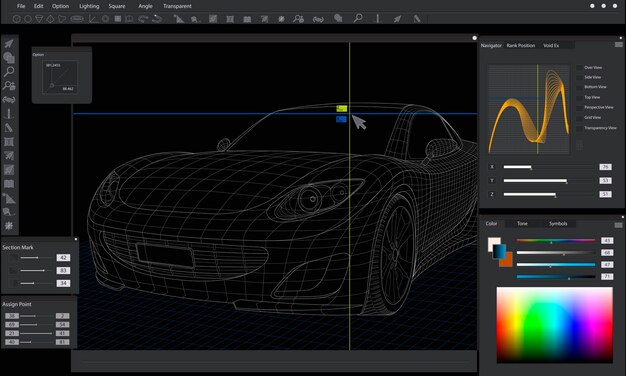

What are the specific CAD software tools for car design and manufacturing?

There are several CAD software tools specifically tailored for car design and manufacturing. These tools offer specialized features and functionalities that cater to the complex requirements of the automotive industry. Some of the prominent CAD software tools used in car design include:

1. CATIA:

CATIA is a powerful CAD software widely used in the automotive industry. It offers a range of specialized modules for automotive design, including surface modeling, mechanical design, and virtual testing.

2. AutoCAD Automotive:

AutoCAD offers an automotive-specific version that provides tools for designing automotive components and assemblies. It’s particularly useful for creating 2D and 3D drawings of car parts.

3. SolidWorks:

SolidWorks is known for its parametric modeling capabilities, making it suitable for designing intricate car components. It also offers simulation and visualization features that aid in car design and testing.

4. Siemens NX:

Siemens NX is an integrated CAD, CAM, and CAE software that’s extensively used in the automotive sector. It covers everything from concept design to manufacturing.

5. Alias AutoStudio:

Alias is a high-end surface modeling software used for designing car exteriors and interiors. It’s particularly popular for creating Class-A surfaces with precision.

Examples of successful car designs that were made possible through CAD drawing?

CAD drawing has played a pivotal role in shaping some of the most iconic and successful car designs in the automotive industry. Here are a few examples:

Tesla Model S:

The Tesla Model S, known for its sleek and aerodynamic design, was made possible through extensive CAD modeling. CAD software allowed Tesla’s design team to create the vehicle’s unique shape, optimize its aerodynamics for efficiency, and simulate various design iterations.

Porsche 911:

The Porsche 911, a classic sports car, has evolved over the years with the help of CAD technology. Engineers use CAD software to refine the car’s curves, optimize weight distribution, and ensure precision in manufacturing.

BMW i8:

The BMW i8, a hybrid sports car, showcases a futuristic design. CAD software enabled BMW to create the car’s distinctive scissor doors, aerodynamic profile, and intricate exterior detailing.

Audi R8:

The Audi R8 is a high-performance supercar with a distinctive look. CAD drawing facilitated the design of its signature LED headlights, aerodynamic body panels, and precise proportions.

Ford Mustang:

The Ford Mustang, an American muscle car, has seen various generations and design updates. CAD technology has been instrumental in reimagining its retro-inspired design while meeting modern safety and performance standards.

In conclusion, the impact of CAD drawing on the car manufacturing industry cannot be overstated. From streamlining design and prototyping processes to enhancing safety, efficiency, and creativity, CAD technology has transformed the way cars are conceptualized, developed, and brought to life. The precision and accuracy offered by CAD tools enable manufacturers to create intricate designs, optimize aerodynamics, and ensure that every component fits seamlessly.

Moreover, if you are looking same benefits for your Car design and drawing? Then Just contact us on info@shalindesigns.com today or drop a message here. We would be happy to discuss your design and drawing idea and how we can help you create stunning and functional CAD drawings of your product that will meet your needs and also increase the beauty of your brand industry.