You have clients excited for immersive walkthroughs, and manufacturers calling for precise simulation?

Design complexity, the pace of work, and the pressing demand to deliver projects on time have significantly increased.

2D CAD simply can’t keep up with modern project demands. This is why industries from manufacturing, construction, to product designing have transitioned from 2D to 3D CAD.

In this post, discover why 2D to 3D CAD conversion is not just a technical shift, it’s a performance multiplier for firms that want to lead.

Why 2D to 3D Conversions Matter Today?

To communicate about the design intentions, engineers and architects have been relying on 2D designs for a long time. Undoubtedly, it’s effective, but with the advancements, there came limitations in 2D. Confused interpretations, restricted capabilities of analysis, and the potential to collaborate were limited. With such limitations, the workflow certainly gets affected.

But, the scenario completely changed when 3D came into role play.

Better communication, improved vision, crisp clarity with every drawing, and the model’s presentation before the final step of moving ahead.

One of the best things that came during this 2D to 3D conversion was the decision-making power of engineers, architects and customers.

This tremendous shift has made a huge impact in various industries, resulting in visualising, simulating, and validating designs in a much better way in the product lifecycle.

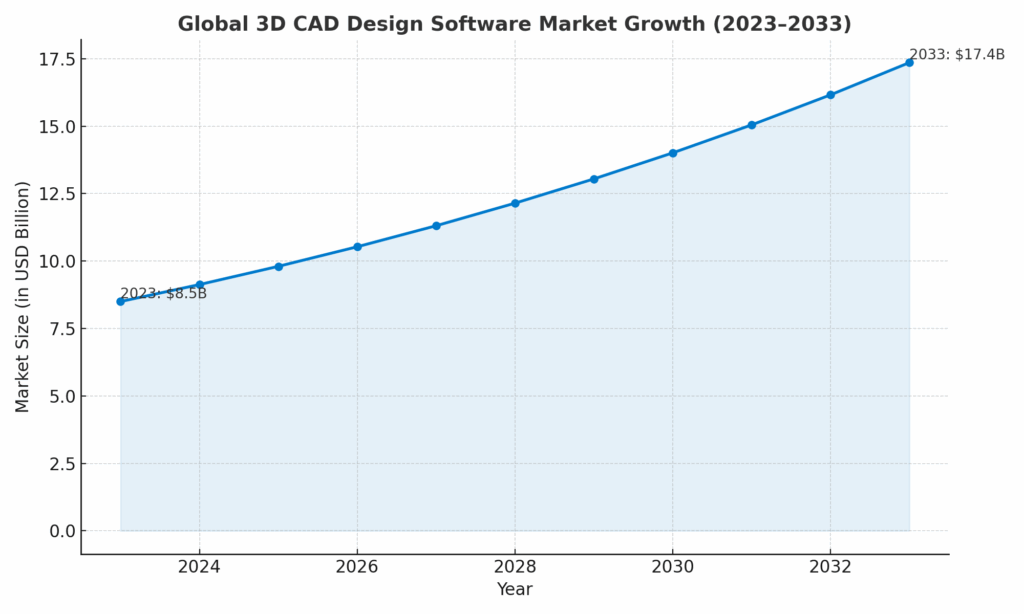

The recent market data highlights this shift.

As per the DataHorizon reports, the global 3D CAD design software market was valued at USD 8.5 billion in 2023. It is projected to nearly double to USD 17.3 billion by the year 2033. This market is growing at a CAGR of 7.4%. Looking at the statistics and predictions of 3D CAD design, this reflects that there is an increasing reliance on 3D modelling for improved accuracy.

This is particularly evident in industrial machinery, where highly complex components must be visualised and validated before production. Speaking alone of the global industrial machinery, it is expected to grow from USD 733.2 billion in 2020 to USD 874.1 billion by 2025. This growth is driven by the need for faster processes and smarter technology. which heavily relies on the advanced CAD tools.

Why the Shift is Accelerating?

So, what’s behind the recent surge in 2D to 3D CAD conversion for manufacturing and engineering industries?

Design Validation is Today’s Need- Not an Option

2D only provides flat drawings: top, front and side views, making the visualisation part quite tough and more time-consuming. With the 3D in the scenario, you can test the simulation virtually and make modifications as many times as possible before even building a single part of any product.

Improved Scope of Communication Across Teams and Others

In the current global manufacturing scenario, design, manufacturing, and production teams are often spread across different countries. For example, engineers might be based in the UK, suppliers are located in Germany, and the execution team is in the UAE. With so many cross-functional teams, having 2D drawings can bring misunderstandings instead of clear, goal-oriented communication.

That’s where people go for CAD conversion services. Converting outdated 2D drawings to accurate 3D models brings everyone on the same page, keeping everyone in sync and on track. These services ensure that everyone involved in the manufacturing and engineering fields works from the same detailed design data.

As a result, teams can collaborate effectively and function as per project timelines.

Advantages of 2D to 3D Conversions

- Designs that Speak for Themselves- 3D models bring concepts to life. They showcase every angle, depth and detail effortlessly. It becomes easy for stakeholders to understand without needing any complex technical interpretation

- Make Changes in Minutes, Not Days- Modify parts, dimensions, or assemblies quickly with amazing tools. 3D CAD streamlines revisions, saving valuable design and approval time.

- Greater Accuracy, Fewer Results- Minimise human error with precise 3D modelling and in-built design validation. What you design is exactly what gets manufactured.

- Worry-Free Automated Documentation- With 3D CAD, it becomes easy to create detailed drawings, BOMs and all the technical specifications. It helps your drawings to stay compliant and consistent. There is less manual effort, and the chances of errors are also minimised.

Read Also : Benefits of 3D Modeling for Design, Development and Manufacturing

Industries Leading the Adoption of 2D to 3D CAD Conversion

Many industries are embracing 2D to 3D CAD conversion services to stay competitive in a fast-evolving design and production landscape.

In automotive and aerospace, 3D models help manage complex assemblies, tight tolerances, and constant innovation through simulation and validation.

Consumer electronics companies rely on precise 3D CAD models for compact components, efficient layouts, and faster design iterations.

Construction and architecture benefit from 3D integration through BIM, improving visualisation, coordination, and project accuracy at every stage.

This shift is more than industry-specific; it’s a global movement. Europe, for instance, is now the second-largest market for 3D CAD design software. The UK, Germany, and France lead adoption, especially in automotive and aerospace.

In the engineering sector where the shift from 2D drawings to 3D models has remarkably transformed the way teams design, review, and communicate. With 2D to 3D CAD conversion services for engineering, companies now gain improved accuracy, better collaboration, and the ability to simulate and optimise designs long before production begins.

Ready to Convert Your 2D Drawings into 3D Reality?

Let our CAD experts transform your flat designs into fully detailed 3D models that simplify communication and speed up production.

A Smart Investment in the Manufacturing Industry

In manufacturing, this transition has delivered even greater advantages. 2D to 3D CAD conversion for manufacturing allows direct integration with CNC machines, 3D printers, and robotic systems. It minimizes material waste, speeds up prototyping, and ensures product designs are production-ready from the start. With 3D CAD modelling services, manufacturers reduce rework, improve precision, and increase overall efficiency across the supply chain.

The competition in the manufacturing sector is becoming increasingly intense. To stay ahead in the market, many companies have adopted 2D to 3D conversion for manufacturing. This makes it easier to-

- Reduce production errors

- Automate the design for the manufacturing process

- Enable virtual assembly and testing

Therefore, investing in 2D to 3D conversion is investing in long-term operational flexibility and relevance.

Final Words

The shift from 2D to 3D is transforming engineering and manufacturing worldwide. At Shalin Designs, we offer expert 2D to 3D conversions, 3D CAD conversion, and full CAD designing and modelling services. Whether you’re upgrading legacy drawings or starting new projects, our solutions ensure accuracy, efficiency, and production-ready results tailored to your industry needs.

Contact Shalin Designs now where your engineering ideas evolve into manufacturable 3D realities.