In the world of mechanical engineering, precision and efficiency are paramount. The integration of 3D CAD modeling has revolutionized the field, offering unparalleled benefits that enhance every aspect of mechanical design. From concept to production, 3D CAD tools are essential for engineers who want to innovate, optimize, and streamline their work. This blog explores how 3D CAD modeling helps mechanical engineers. It improves precision, efficiency, and innovation worldwide.

The Importance of 3D CAD in Mechanical Engineering

3D CAD (Computer-Aided Design) modeling is a technological advancement that has fundamentally transformed the way mechanical engineers approach design. 3D CAD lets engineers make detailed, 3D models that can be viewed from any angle, unlike traditional 2D drafting. This capability is crucial in mechanical engineering, where understanding the spatial relationships and physical characteristics of components is essential.

One of the key advantages of 3D CAD modeling in mechanical design is its ability to simulate real-world conditions. Engineers can test components in the digital model under different conditions. This reduces the need for physical prototypes, saving both time and resources.

Enhancing Precision in Mechanical Design with 3D CAD

Precision is a cornerstone of mechanical engineering. The accuracy of measurements, tolerances, and fits can make the difference between a successful product and a costly failure. 3D CAD modeling in engineering design offers a level of precision that was previously unattainable with manual drafting methods.

With 3D CAD, engineers can create detailed models that include every component, down to the smallest screw or bolt. These models are easy to manipulate to ensure all parts fit perfectly, reducing the risk of manufacturing errors. Furthermore, 3D CAD tools allow for automatic calculation of dimensions and tolerances, which enhances accuracy and consistency across the design.

Efficiency of 3D CAD in Mechanical Design

Efficiency is another major benefit of using 3D CAD for mechanical engineering design. Traditional design processes often involve multiple stages of drafting, prototyping, and testing, each of which can be time-consuming and costly. 3D CAD lets mechanical engineers create and change designs quickly, run simulations, and make adjustments without building physical models. This streamlines the design process.

Iterating designs quickly saves time and lets engineers explore more options, creating better products. 3D CAD models are easy to share and collaborate on across teams and locations. This makes global mechanical engineering projects more efficient.

Mechanical Design Innovation with 3D CAD

Innovation is at the heart of mechanical engineering, and 3D CAD modeling plays a critical role in driving this innovation. 3D CAD empowers engineers to innovate with its flexible tools.

3D CAD has revolutionized mechanical design, enabling the creation of more complex and efficient systems. Engineers can now design intricate geometries, optimize for weight and strength, and integrate advanced materials digitally. This has led to breakthroughs in fields like aerospace, automotive, and robotics.

Engineering Made Visual, Accurate, and Scalable

Turn blueprints into high-precision digital 3D models that transform your engineering workflow and product visualization.

Mechanical Design Optimization with 3D CAD

Optimization is a key aspect of engineering design, and 3D CAD tools for mechanical design services offer numerous features that aid in this process. With 3D CAD, engineers can perform detailed analysis and simulations to optimize designs for performance, cost, and manufacturability.

Using 3D CAD in mechanical engineering lets you do finite element analysis (FEA) right in the CAD software. FEA allows engineers to simulate how a design will respond to various physical forces, such as stress, vibration, and heat. Engineers can identify potential issues early in the design process. This allows them to make informed decisions and optimize the design before production.

Additionally, mechanical engineering design optimization with 3D CAD includes tools for optimizing manufacturing processes. Engineers use CAD data to create detailed instructions for machines like CNCs and 3D printers. This ensures parts are made exactly right and with little waste.

Mechanical Engineering Design Process with 3D CAD

The design process in mechanical engineering is a complex and iterative journey. From initial concept to final production, every stage requires careful planning, analysis, and validation. 3D CAD modeling empowers mechanical engineers with the tools to excel in every stage of the process.

During the concept phase, 3D CAD allows engineers to quickly create and visualize ideas. These models can then be refined and tested using simulations, reducing the need for costly physical prototypes. As the design progresses, 3D CAD mechanical design solutions let engineers make changes easily, work with team members, and make sure the final design meets all requirements.

Improved documentation and production in the final stages of mechanical engineering design are enabled by 3D CAD modeling. Detailed CAD models can be used to create technical drawings, assembly instructions, and other documentation required for manufacturing. This ensures that the transition from design to production is as smooth and error-free as possible.

Benefits of 3D CAD Modeling in Mechanical Engineering Applications

The applications of 3D modeling for mechanical engineering are vast and varied, spanning numerous industries and disciplines. 3D CAD modeling helps engineers design complex machinery, develop innovative products, and optimize manufacturing processes.

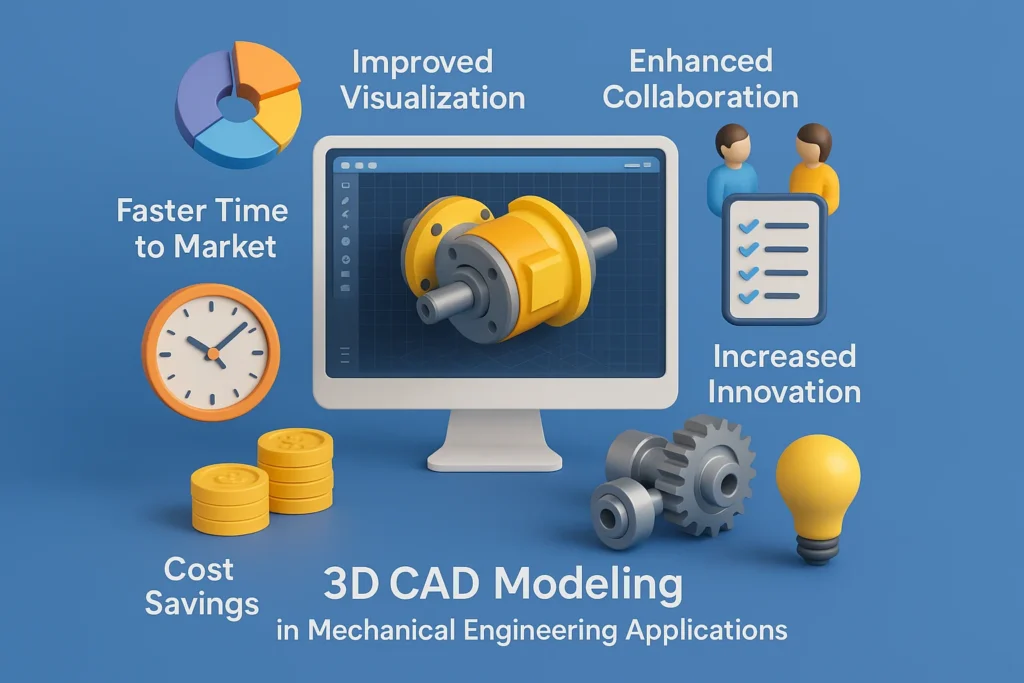

Some of the benefits of 3D CAD modeling in mechanical engineering applications include:

- Improved Visualization: 3D CAD models offer a realistic view of the final product. This helps engineers understand and share design ideas better.

- Enhanced Collaboration: 3D CAD models can be easily shared and collaborated on by teams across the globe.

- Faster Time to Market: 3D CAD speeds up product development by streamlining design and reducing the need for physical prototypes.

- Cost Savings: Testing and optimizing designs digitally can save money on prototypes and production errors.

- Increased Innovation: 3D CAD provides the flexibility and power needed to explore new design possibilities and create cutting-edge products.

Conclusion

3D CAD modeling has transformed mechanical engineering design. It offers precision, efficiency, and innovation. CAD tools optimize design, enable simulations, and enhance collaboration. As technology advances, their impact will grow, leading to more innovation and excellence.

3D CAD helps companies compete, make better products, and succeed in today’s fast-paced world.

Shalin Designs provides mechanical engineering solutions globally. Clients are based in the USA, UK, Canada, Australia, Europe, Singapore, Norway, Ireland, and the UAE. We use the latest 3D CAD technology.

Ready to unlock the full potential of 3D CAD modeling for your mechanical engineering projects? Let Shalin Designs be your innovation partner. Contact us today or email us info@shalindesigns.com to discuss your specific needs and explore how our expertise can help you achieve your design goals.