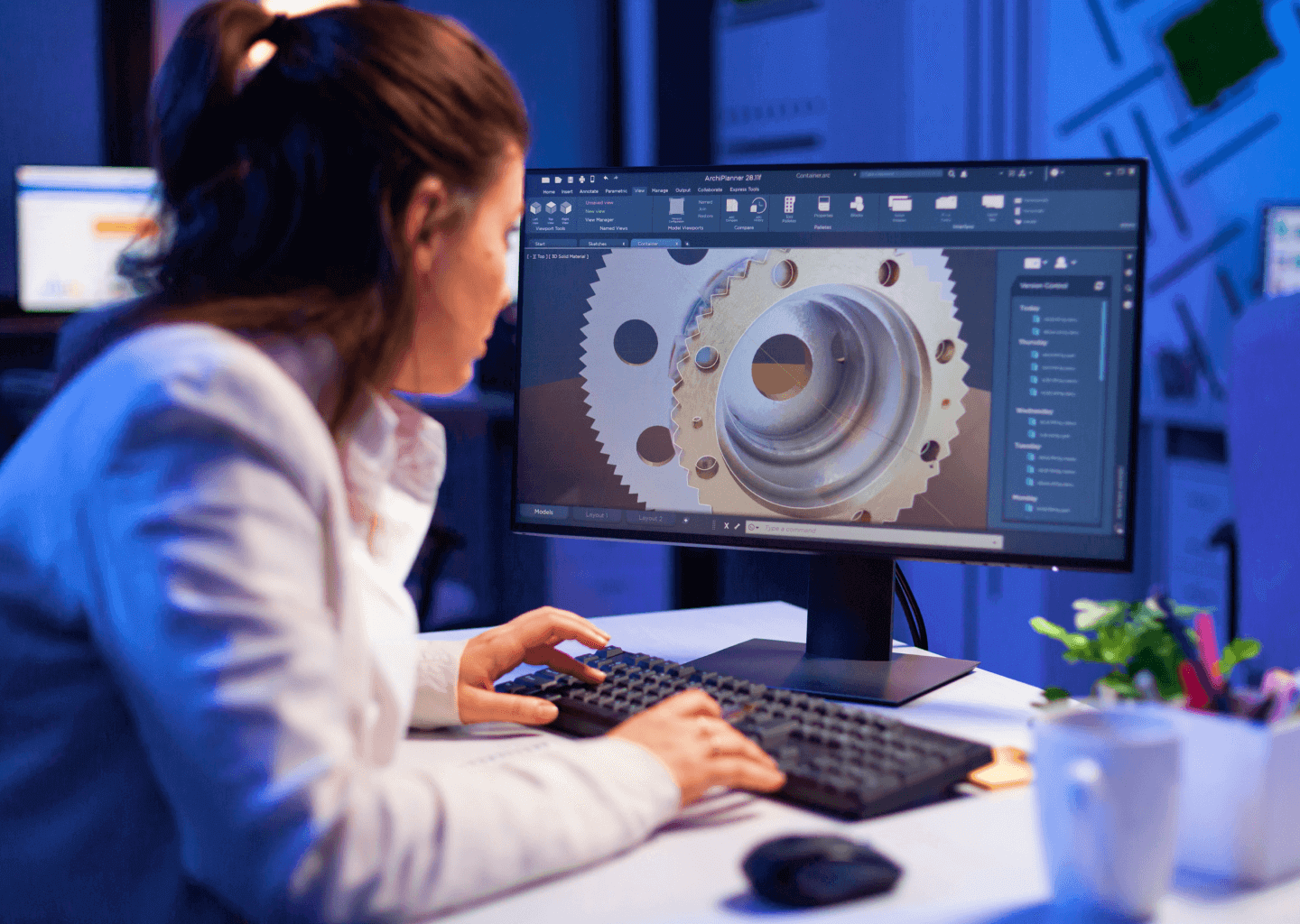

Smart manufacturing industries are making massive transformations with the help of computer-aided designs services. Thanks to Industry 4.0, from drafting designs and creating prototypes to making changes and analyzing user experience, advanced CAD software has become indispensable to furniture designers.

In this blog, we’ll inform you of the various tools and features available in a CAD system that every designer should utilize. These analytical and collaborative technologies empower professionals to curate efficient and high-performing products.

Digital Twin Technology

This technology lets interior designers create virtual models of an object or system. To design furniture, designers often use CAD software to create digital twin models of furniture. This allows furniture designers to simulate the physical performance of the models. That way, they can make real-time modifications before manufacturing.

Significant applications of digital twin technology in Industry 4.0:

– Prototyping

Designers use advanced CAD software to create product prototypes. A robust prototype enables designers to test the product’s various configurations and work efficiency. This reduces the chances of manufacturing errors.

– Performance Analysis

Digital twin technology allows design experts to analyze how the properties of furniture will react in a given environment. Such analyzing tools help furniture designers make necessary modifications, increasing the functionality and durability of the furniture pieces.

Embrace the Future of Design with CAD Innovation

Unlock the power of Industry 4.0 with intelligent CAD solutions that streamline your product development and manufacturing workflows.

IoT Integration with CAD Systems

The Internet of Things connects devices to the Internet. When integrated with CAD software, designers can exchange data and collaborate in real time. It further offers valuable insights that improve the furniture designing process.

Here are some benefits:

– User Insights

Innovative furniture with IoT integration allows designers to gather and exchange data on usage patterns. Therefore, the tool helps optimize the furniture and its future variations.

– Improved Functionality

IoT in manufacturing CAD programs often comes with features like built-in sensors and app-controlled functionalities. These additional help designers enhance user experience and product performance.

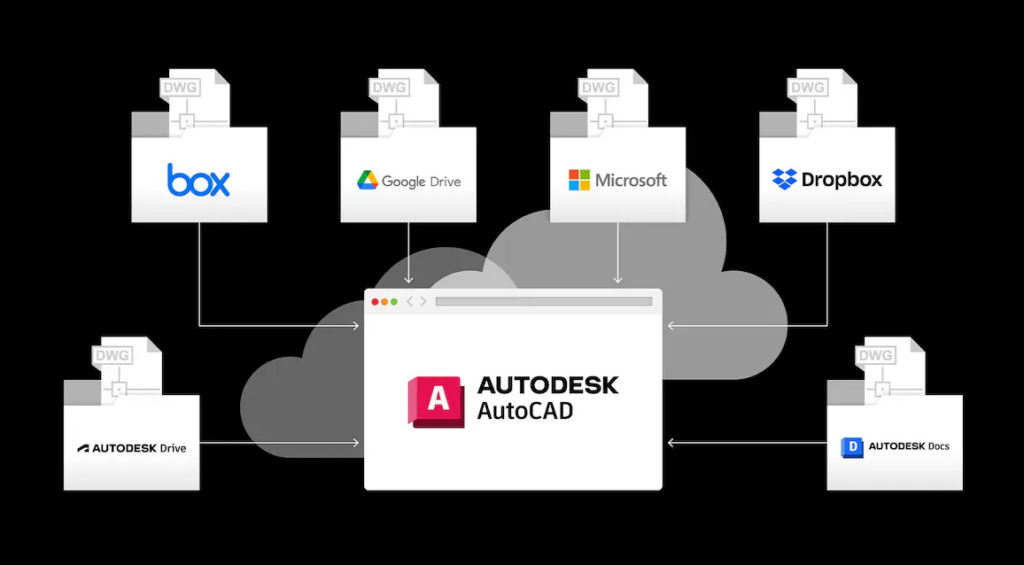

Cloud-Based CAD and Collaboration Tools

Are you looking for ways to connect with your team remotely? Cloud-based CAD technology can be your answer. Furniture designers in the industry 4.0 can seamlessly collaborate with their team and work in real-time. Industry experts point out that cloud-based CAD is highly beneficial for 3D furniture design experts who work with clients and manufacturers from diverse regions.

Here are a few advantages:

– Real-time Collaboration

You can always stay connected with your team, no matter where you’re located. Cloud-based CAD allows your team to share models, exchange information, and stay in the loop with the latest modifications.

– Accessibility

Smart furniture designers in the UK often have to work remotely. This integrated CAD software empowers designers to access data and design from anywhere. Such flexibility benefits designers and improves their productivity.

Data Analytics and Insights from CAD Data

Every product design can be improved by analyzing past data. CAD systems generate a vast amount of data. By analyzing this information, insights can help you increase product efficiency. Furthermore, designers can use this data to modify user experience as well. This data-driven approach elevates creativity and enhances the product to meet market demands.

Key benefits of this tool include:

– Trend Identification

When analyzing data, designers can quickly figure out the latest trends. They can identify the same in materials, styles, and also consumer preferences.

– Performance Metrics

This metric informs the designer how their product will perform in the real world. Accordingly, furniture designers can improve or modify their designs to avoid unnecessary rework later.

How CAD Supports Sustainability in Smart Manufacturing

Some of the key areas where the integration of CAD tools supports sustainability in smart manufacturing are:

– Material Optimisation

Computer-aided design tools help designers simulate furniture made of various materials and check the impact of the environment on it. Upon analyzing furniture materials, the designers can finally choose sustainable materials while creating a 3D CAD model.

– Efficient Prototyping

Engineers can run multiple tests of a product with the help of digital twins and virtual prototyping. The furniture designers don’t need physical samples for this process. Furthermore, this reduces the material waste during the design phase.

– Energy-efficient Manufacturing

Manufacturing systems can be significantly optimized when CAD software is integrated into them. For instance, engineers can analyze machine efficiency and energy consumption of the machines. That way, they can adjust their operations and reduce their carbon footprint to a great extent.

Conclusion

The furniture industry is continually evolving with computer-aided designs at the helm. The CAD software and its various integrations enhance the smart future designs in Industry 4.0. Being a furniture or interior designer, you can leverage diverse technologies to create sustainable and intuitive designs.

Do you want technologically optimized and creative furniture designs? Don’t wait anymore. Visit Shalin Designs today and experience professional designers turning your ideas into reality. With years of experience, the dedicated team brings an array of knowledge and skills, giving you complete control to suggest and make changes.