Tired of cabinetry surprises that ruin timelines, inflate budgets, and leave clients frustrated?

That’s the reality of traditional cabinetry design, avoidable mistakes that eat into your margins and damage trust. Most designers still rely on 2D sketches that lack clarity, scale, and visual confidence.

You’re losing money every time a cabinet doesn’t fit, a drawing gets misread, or a client changes their mind too late.

But in a market where precision and speed matter more than ever, that approach is costing you.

3D CAD design for custom cabinetry has emerged as a modern necessity, providing you with a competitive edge.

With precise virtual models, instant visualization, and measurable accuracy, you gain control before a single cut is made. No more guesswork. No more back-and-forth with confused clients. Just crystal-clear plans and seamless execution.

In this post, we’ll highlight the benefits of 3D CAD in custom cabinetry. We will also break down the complete workflow, so you can see exactly how to integrate it into your existing design process.

But, before that, let’s explore the market overview.

3D CAD Software in the Cabinetry Industry

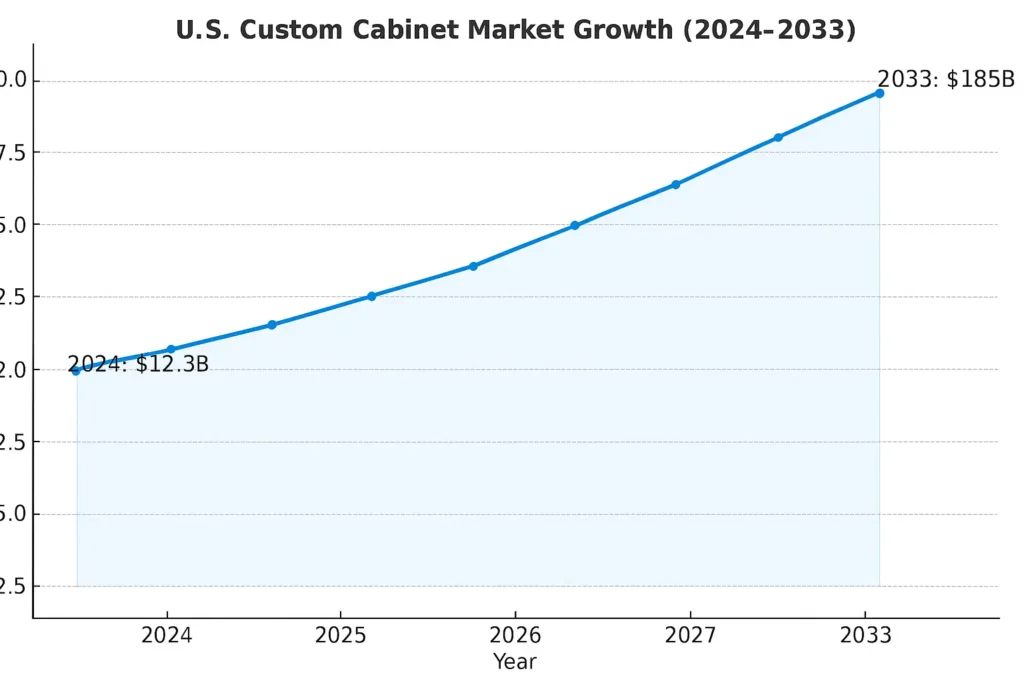

The custom cabinet market is experiencing rapid growth. It was worth $12.3 billion in 2024, and is projected to grow by $18.5 billion by 2033.

However, what are the aspects that are driving this market expansion?

Is it the desire to have bespoke cabinets within smart and stylish homes?

Yes!

Today, everyone cares about styles, functions, innovative features, and aesthetics.

With the help of 3D CAD software, it’s becoming relatively easy to see their cabinet, even before it’s built.

No guesswork, just clear designs for better clarity.

After all, who won’t like to explore some layouts, colour combinations, finishings, and more?

And it’s not just about looks. Cabinets today are made for smart homes, with hidden tech and clean finishes. 3D CAD helps bring these ideas to life. 3D cabinet design services help bring these ideas to life.

It also supports sustainable design, which more customers are now asking for.

In short, 3D modeling for cabinet design is making custom cabinetry faster, smarter, and better.

Benefits of 3D CAD for Custom Cabinetry

Often, as we hear the term “3D services”- the very first thing, we would think is, “it would be very costly”, “why to go for fancy designs when with 2D we can get the idea”- more so like that. Amidst the discussions and confusions whether or not, shall you opt for 3D, here are some underlying advantages that will help you to decide.

1. Feel the Space

Has it even happened to you that a well-looking 2D CAD cabinet design turned into a cabinet that went contrast to what you wanted?

Poor dimension executions or surface-level clarity, the 2D to real transitions went like “What is this?”

Flat and straightforward drawings led to gaps and misunderstandings in communication, resulting in unexpected outcomes or costly errors.

Having 3D CAD cabinet design services allows you to see the design from every angle, how tall cabinets look next to windows. It will also indicate the amount of walking space you will have between the cabinets and the wall or furniture. It even lets you visualise how natural light would flow into your cabinetry space during the day.

2. Accelerate Client Approvals

Let’s admit, getting approval for each element from a client is not only time-consuming but a long tiresome process. Unless, he’s not assured about the cabinetry design, there are endless loops of resending designs and asking some or the other approvals.

The plain designs of 2D bring a lack of clarity, as clients struggle hard to visualise.

3D modelling for cabinet design solves this as clients can see how the finished product would actually appear and not merely imagine. This means the more clarity your client has, there will be a faster approval process.

3. Solve Issues Before They Happen

Ever built a cabinet that didn’t open properly because it hit a wall? Yeah, painful.

With 3D cabinet design services, you can simulate every function- how doors swing open, how drawers pull out, and whether handles get in the way. It’s like a dry run before the real thing. You solve problems before they become expensive fixes.

4. Make Changes Without Spending More

Clients love changing their minds, right?

Instead of redrawing from scratch, 3D CAD cabinet design lets you tweak dimensions, change door styles, swap colours- all within seconds. That means less frustration, faster versions, and a happier client.

5. Utilization of Materials in a Smarter Way

One of the best aspects of 3D CAD is that it enables you to plan more effectively and conserve materials in the long run.

You will know precisely how many sheets of plywood, how many hinges, and how much edge banding you need. Nothing gets wasted. Nothing gets over-ordered.

Investing in 3D cabinet design services for custom cabinetry is not expensive, but it is highly valuable.

6. Increase Your Profit Margins

Want to upscale your business quickly? 3D CAD helps you achieve this. Use 3D CAD to break down every part of the project, from carcasses and hardware to finishes and fittings. It instantly gives you accurate costings, helping you quote faster and smarter.

Step-wise Workflow of 3D CAD Cabinetry

Creating custom cabinetry isn’t just about picking up the finishes or choosing textured panels. It’s the well-planned, properly structured, detailed process that demands absolute precision. 3D CAD software ensures that your ideas are thoroughly evaluated across various aspects and then transformed into a practical product.

1. Initial Client Consultation and On-Site Visit

Always remember that the first consultation is important. It’s all about the client’s vision and what they require. If there is clarity on both ends, then the entire flow would be smooth.

- Initial discussion with the client about style, materials, storage needs, space usage, and budget.

- A site visit (if necessary) can be conducted to measure the exact dimensions and note any architectural features, such as sloped ceilings or awkward corners.

How will this help?

At the end of this phase, you will walk out with all the brief requirements of the client, possibilities, and limitations. You will also need to take the necessary measurements of the space where the cabinet needs to be installed.

2. Early Stage Draft Design

Before making the transition to 3D, the 2D drawing enters active mode.

Here’s what can happen in this stage-

- Designers create basic floorplans and elevations using CAD software.

- The goal here is to map out the placement of each cabinet, drawer, or appliance.

- This provides a bird’s-eye view of the layout before it is rendered in 3D.

How will this be an advantage?

Once you receive the rough draft, you can present it to the client. For all the missing spots, errors, changes, and critical feedback, this draft would work best. All the changes and feedback given here can be smoothly implemented in the upcoming stage.

3. 3D Modeling and Visualization

This is where all the interesting things come into action.

Using advanced 3D cabinet design services, the designer builds detailed, scaled 3D models of the entire cabinetry system. In this model, there are several things which are included, such as-

- Cabinet frames, hinges, and doors

- Textures and finishes

- Context of the space (hall, bedroom, lounging areas, etc.)

How will this help you?

Well, this would help you and your client, more specifically. They would get to see what their vision would look like when it would come to life.

4. Client Review and Design Refinement

Sometimes, the client requests additional changes after reviewing the 3D vision. It could be slight tweaks or some minor shifts in dimensions. With 3D CAD, you can only work on those changes rather than the entire cabinetry design from scratch.

In this phase, here are the things that can function-

- Clients provide feedback (e.g., changing colours, adjusting sizing, adding pull-outs, etc.).

- The designer makes real-time modifications in the 3D model

- Multiple layout or style options can be presented for comparison

How will this be an advantage?

You will get a functionally solid design approved by the client that’s ready to go for the production stage.

5. Production-Ready Technical Drawings

The approved 3D design is required for precise technical drawings. These drawings would include-

- Exact dimensions and quantities of panels and pieces that need to be cut.

- Various diagrams that show different parts are connected.

- Detailed specifications on slides, handles, and other hardware information

- A brief guide on how to put everything together precisely and correctly.

- A breakdown of how much material is needed, helping with budgeting and reducing waste.

How will this help you?

You get a complete documentation package that’s ready for use in a workshop or directly with a CNC machine.

6. Final Site Delivery and Setup

With the approved design and detailed technical drawings in place, your project moves into full production and completion.

In this stage, here’s all that can take place-

- The 3D CAD data is translated into machine-ready formats (CAM files), allowing CNC routers to cut and drill each component with pinpoint precision.

- In traditional workshops, printed technical drawings and cut lists guide manual fabrication with equal accuracy.

- Once completed, the finished cabinets are delivered to the site and professionally installed. Fitters follow layout diagrams and assembly instructions generated from the CAD model, ensuring a smooth and efficient installation.

- Any minor on-site tweaks are noted and updated directly in the CAD files.

How will this be an advantage?

A high-quality, custom-built cabinetry solution delivered and installed exactly as designed, backed by accurate documentation for ongoing support and future-proofing.

Final Words

Using 3D CAD in custom cabinetry isn’t just about looking modern. It’s all about-

- Eliminating errors

- Impressing clients visually

- Streamlining production

- Saving time and material costs

Shalin Designs has built its reputation on a transparent and efficient custom kitchen cabinetry CAD workflow, designed to eliminate errors and save time. From expert consulting teams to experienced designers, we have everything you are looking for. Contact Us today for expert 3D CAD cabinet design services tailored to architects, interior designers, and manufacturers. Let’s turn your vision into detailed, production ready designs.